Leading

Horizontal Autoclave Manufacturer in India: Quality, Reliability, and

Affordability

In the

ever-evolving landscape of medical and laboratory equipment, the

importance of quality sterilization cannot be overstated. Hospitals, research

facilities, and pharmaceutical companies rely heavily on advanced sterilization

equipment to ensure the safety and efficacy of their operations. As a result,

the demand for reliable autoclaves is on the rise, making the role of

horizontal autoclave manufacturers in India pivotal.

Why Choose

a Horizontal Autoclave Manufacturer in India?

When it

comes to horizontal

autoclave manufacture in India, the country has emerged as a

frontrunner in producing high-quality, durable, and efficient autoclaves.

Indian manufacturers have made significant strides in technology and

innovation, offering state-of-the-art solutions that cater to the diverse needs

of various industries.

Quality

Assurance

One of the

primary reasons for the growing popularity of horizontal autoclave

manufacturers in India is their unwavering commitment to quality. These

manufacturers adhere to stringent international standards, ensuring that their

products meet the highest benchmarks in terms of performance and reliability.

Whether it's for medical, research, or industrial applications, customers can

rely on Indian-made autoclaves to deliver consistent and dependable results.

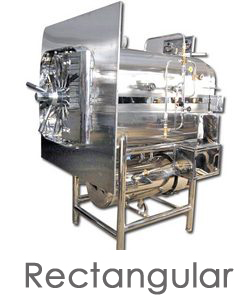

Wide Range

of Products

Another

distinguishing feature of horizontal

autoclave manufacture in India is the extensive range of products

available. Manufacturers offer a variety of models, catering to different

capacities, functionalities, and price points. This diversity allows customers

to find the perfect autoclave that aligns with their specific requirements

without compromising on quality or performance.

Horizontal

Autoclave Price in India: Affordability Meets Quality

When it

comes to purchasing an autoclave, cost-effectiveness is often a significant consideration

for buyers. Horizontal

autoclave price in India offers a compelling proposition, striking the

perfect balance between affordability and quality.

Competitive

Pricing

One of the

key advantages of choosing a horizontal

autoclave manufacturer in India is the competitive pricing of their

products. Despite offering world-class quality and cutting-edge features,

Indian manufacturers manage to keep their prices competitive, making their

autoclaves an attractive choice for budget-conscious customers.

Value for

Money

Investing in

a horizontal autoclave from a

reputable manufacturer in India is a decision that promises excellent value for

money. Not only do customers benefit from competitive pricing, but they also

get a reliable and durable product that requires minimal maintenance, thereby

reducing long-term operational costs.

Conclusion

The role of

horizontal autoclave manufacturers in India in shaping the global

sterilization equipment market cannot be ignored. With their unwavering

commitment to quality, innovative product offerings, and competitive pricing,

Indian manufacturers have carved a niche for themselves in the industry.

Whether you

are in the healthcare sector, research industry, or any other field requiring

sterilization solutions, opting for a horizontal autoclave manufacturer in

India is a decision you won't regret. Their products offer a perfect blend of

quality, reliability, and affordability, making them an ideal choice for

discerning customers.

In

conclusion, as the demand for advanced sterilization equipment continues to

grow, horizontal autoclave manufacturers in India are poised to lead the way,

setting new benchmarks in excellence and innovation. So, if you're in the

market for a reliable and efficient autoclave, look no further than the leading

manufacturers in India, where quality meets affordability.

Comments

Post a Comment